Testing and Inspection Equipment

When quality matters, precision tools matter even more. CSI’s in-house inspection and testing equipment allows us to validate every part we produce, not just for fit and finish, but to ensure each component is fit for use and built for durability. From first article inspection to final shipment, we use rigorous verification processes to ensure every component meets your exact requirements. Our team is trained on state-of-the-art metrology and testing technology, empowering us to catch potential issues early and deliver results that are both reliable and repeatable.

What CSI’s Testing and Inspection Capabilities Mean for You

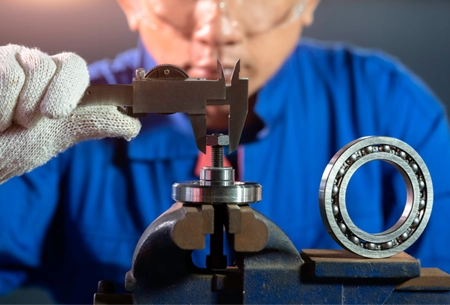

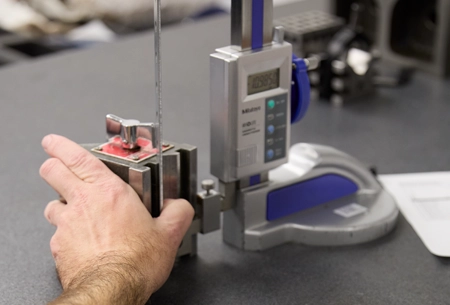

Dimensional Inspection

From CMMs and vision systems to digital calipers and thread gauges, our dimensional tools ensure your parts are exactly to spec, every time.

Material Verification

We use hardness testers, spectrometers, and other material analysis tools to confirm properties like strength, composition, and surface hardness conform to your specs.

Performance Testing

In select applications, we test parts under real-world conditions — from torque and tensile load to environmental simulation — to verify performance over time and under stress.

Integrated Process Controls

Our inspection isn’t just post-production. We embed testing and validation checkpoints throughout the manufacturing lifecycle — aligned with our proprietary Phase Gate Quality Model — to ensure quality is built in.

Request a Full Capabilities List

Need a breakdown of our inspection capabilities or want to schedule a first article review? We’re happy to provide equipment lists and technical details to meet your audit or documentation needs.

Explore Our Quality Capabilities

ISO Certification

Learn More

Phase Gate Quality Process

Learn More

PPAP Process

Learn More

Quality Assurance

Learn MoreReady to Build What’s Next?

Let’s turn your spec into a solution – and your supply chain into a competitive advantage.