Quality Assurance

At CSI, the quality we espouse isn’t a mere talking point or check box — it’s the culture we uphold, the central process we follow, and a promise we deliver. Our proprietary Phase Gate Quality Control Model ensures that every component we manufacture meets the highest standards of performance and consistency, from design through delivery. Combined with robust ISO certifications, advanced inspection capabilities, and deep engineering rigor, our approach eliminates surprises and builds trust and confidence.

What We Deliver

Higher Product Reliability

Each product is reviewed and validated at multiple stages, reducing the likelihood of failure in production or in the field. Our rigorous inspection processes deliver reliable performance and fewer surprises.

Faster, Smoother Launches

Our structured model ensures on-time delivery by flagging risks early and keeping cross-functional teams aligned. That means fewer delays, better outcomes, and smoother customer experiences.

Proven Results

Our DPMO (Defects per Million Opportunity) metrics are consistently world-class — a reflection of the discipline, data, and decision-making built into every step of our quality process.

Customer-Specific Documentation

Whether it’s PPAP packages, APQP requirements, control plans, test data, or material certificates, we manage the documentation that helps customers meet compliance requirements and internal standards.

What Sets Our Quality Program Apart

CSI embeds quality into everything we do.

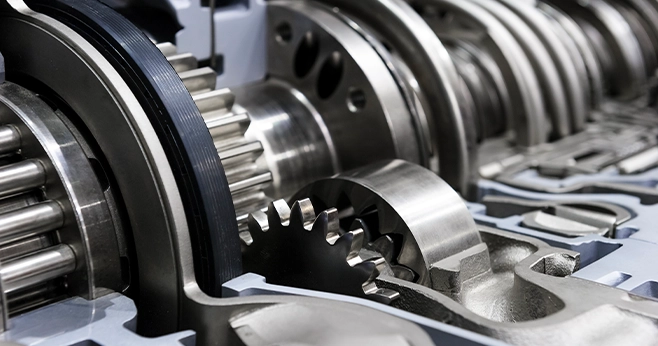

Our proprietary quality system is purpose-built for the complexity of global manufacturing, combining a tailored APQP model with our robust Phase Gate Quality Process. Designed by engineers, refined through real-world application, and executed with uncompromising precision, it’s how we deliver diverse products across multiple industries with confidence, consistency, and reliability.

- Process-Driven Precision: Our Phase Gate Quality Model ensures each part is validated at key stages — from initial feasibility to final shipment — for maximum reliability and compliance.

- Proactive Risk Mitigation: Advanced Product Quality Planning (APQP), Failure Mode & Effects Analysis (FMEA), and Statistical Process Controls (SPC) are built into our process to identify issues early and eliminate them.

- Certified Confidence: With ISO 9001:2015-certified U.S. facilities and internationally compliant manufacturing centers, we deliver consistent quality that meets or exceeds global standards.

Explore Our Quality Capabilities

ISO Certification

CSI’s ISO-certified operations reflect our unwavering commitment to globally recognized quality standards, driving continuous improvement, traceability, and accountability.

Learn More

Phase Gate Quality Control Process

From first spec to final shipment, our proprietary process ensures consistent results through rigorous control, documentation, and engineering oversight at every critical stage.

Learn More

PPAP Process

Our tailored PPAP provides confidence in fit, form, and function, delivering peace of mind for OEM and Tier 1 requirements where performance is non-negotiable.

Learn More

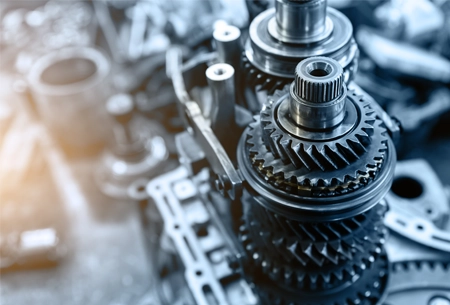

Testing and Inspection Equipment

With a suite of advanced metrology and inspection tools, CSI validates quality through data, delivering the assurance you need for high-performance applications.

Learn MoreReady to Build What’s Next?

Let’s turn your spec into a solution – and your supply chain into a competitive advantage.