Precision Components

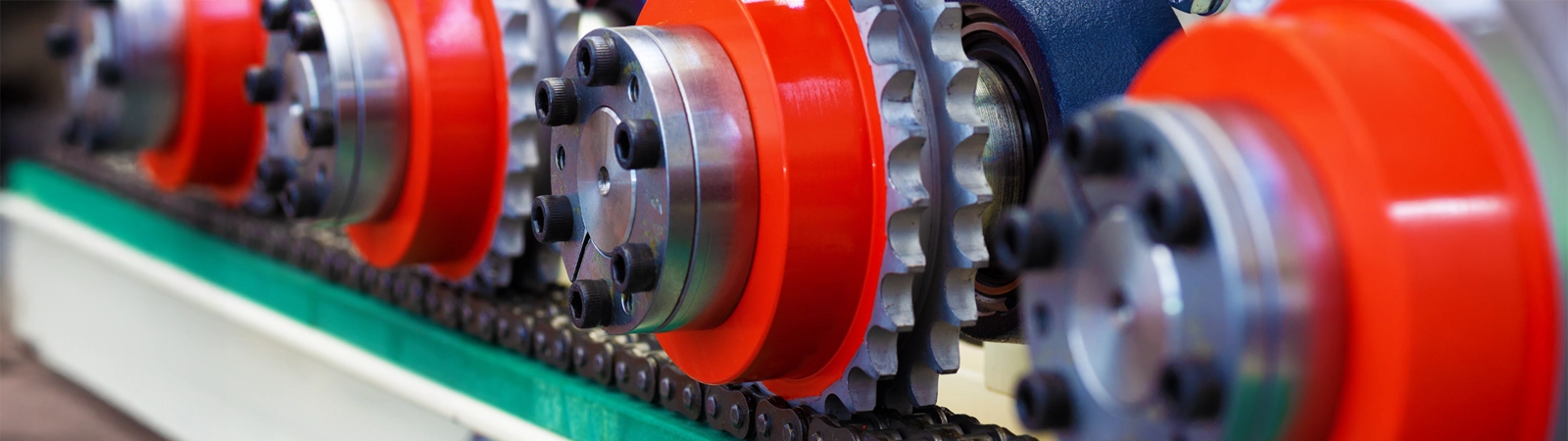

CSI provides precision components—bearings, pulleys, gears, sprockets, and more—that are critical to the performance and longevity of complex equipment. Beyond individual parts, we integrate these components into full-system builds, reducing supplier complexity while ensuring tight design alignment. With deep materials expertise and rigorous quality standards, CSI delivers reliable, close-tolerance solutions engineered for demanding applications.

Our Capabilities

We supply high-precision, custom-built components to exacting specifications, supporting tight tolerances, unique geometries, and demanding performance standards. Whether you’re seeking low-friction bearings for high-speed applications or load-bearing gears for heavy-duty environments, our team ensures each part meets your requirements.

Typical Components:

- Ball and roller bearings

- Spur, helical, and bevel gears

- Timing pulleys and sheaves

- Sprockets and drive wheels

- Idlers and tensioners

- Bushings and sleeves

Materials:

- Carbon and alloy steels

- Stainless steel

- Brass and bronze

- Plastics (nylon, acetal, UHMW)

- Powdered metal

If needed, CSI will help you select the right material, provide machining and finishing, as well as kitting and assembly services for a variety of applications.

Certified Quality You Can Count On

Every component we deliver is backed by rigorous quality assurance and ISO 9001:2015 certification — so you can trust what you get from CSI.

Finishing Options

The job isn’t done when a part comes off the line! CSI offers a wide range of finishing services to enhance performance, protect against wear, and meet your exact specs — whether for aesthetics, corrosion resistance, or mechanical integrity.

Common Finishing Services Include:

- Powder coating

- Anodizing

- Zinc plating

- E-coating

- Heat treating

- Deburring and polishing

- And more

Ready to Build What’s Next?

Let’s turn your spec into a solution – and your supply chain into a competitive advantage.