Metal Fabrications

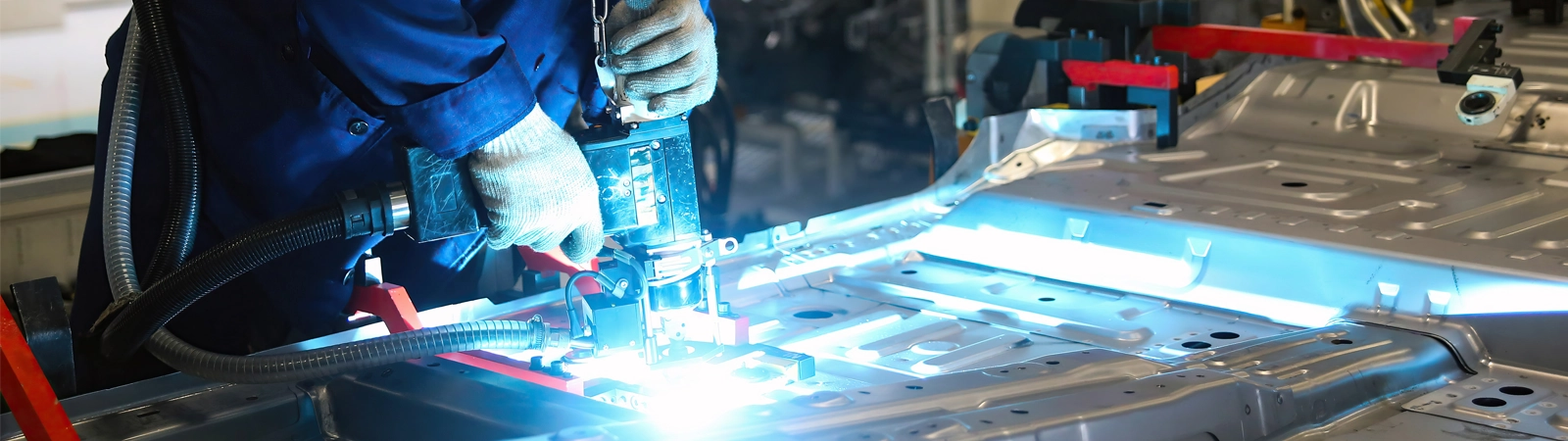

CSI delivers high-quality metal fabrications at scale, from simple bent components to complex, multi-part welded assemblies. Whether you’re working with sheet metal or heavy-gauge steel, we bring the engineering expertise, process flexibility, and finishing options needed to meet demanding performance and durability standards.

With our vertically and horizontally integrated services, we manage every stage of your fabrication project, including tooling, forming, welding, finishing, and final inspection. Our team partners with you to determine the best approach based on form factor, load, environmental conditions, and cost. The result is a better-built component, delivered on time and at scale.

Our Capabilities

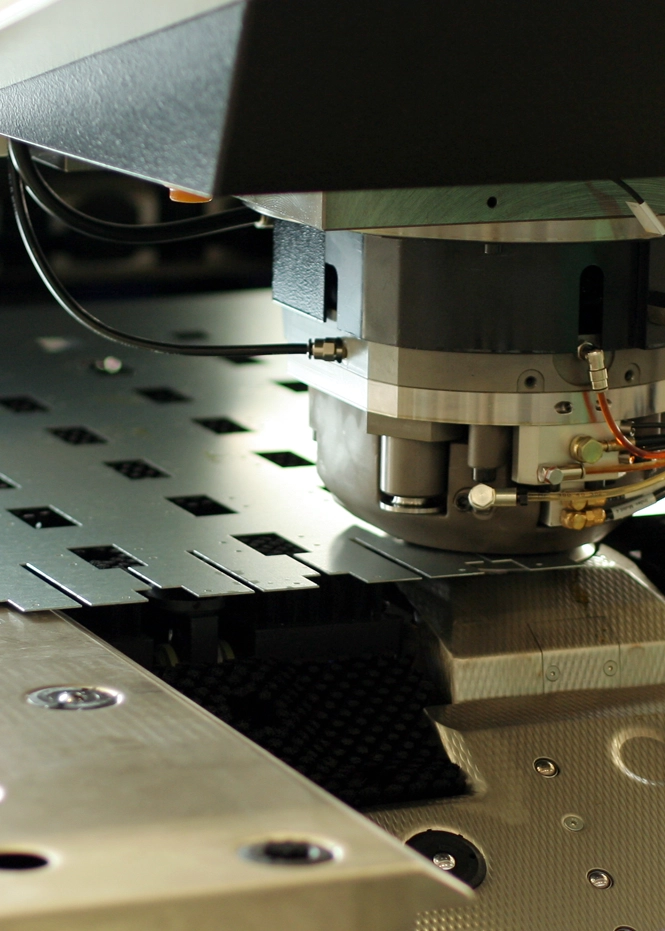

CSI’s fabrication capabilities are engineered for precision, repeatability, and scalability. Every project starts with understanding your goals and matching them with the right fabrication method. Our extensive in-house capabilities and deep process expertise allows us to deliver parts built exactly for your performance, budget, and timeline needs.

Fabrication Processes:

- Laser cutting and waterjet cutting

- Press brake forming and roll forming

- Manual and robotic MIG and TIG welding

- Spot welding and resistance welding

- Stamping (progressive and compound dies)

- Structural fabrication and frame building

- Light and heavy-gauge sheet metal fabrication

- Soft tooling and short-run production

- Assembly and subassembly integration

Materials Used:

- Carbon steel (cold-rolled, hot-rolled, galvanized)

- Stainless steel (304, 316, 409, etc.)

- Aluminum (5052, 6061, 7075, etc.)

- Copper

- High-strength and wear-resistant alloys

- Perforated, expanded, and embossed metals

- Pre-painted or coated sheet stock

If needed, CSI will help you select the right material, provide machining and finishing, as well as kitting and assembly services for a variety of applications.

Certified Quality You Can Count On

Every component we deliver is backed by rigorous quality assurance and ISO 9001:2015 certification — so you can trust what you get from CSI.

Finishing Options

The job isn’t done when a part comes off the line! CSI offers a wide range of finishing services to enhance performance, protect against wear, and meet your exact specs — whether for aesthetics, corrosion resistance, or mechanical integrity.

Common Finishing Services Include:

- Powder coating

- Anodizing

- Zinc plating

- E-coating

- Heat treating

- Deburring and polishing

- And more

Ready to Build What’s Next?

Let’s turn your spec into a solution – and your supply chain into a competitive advantage.