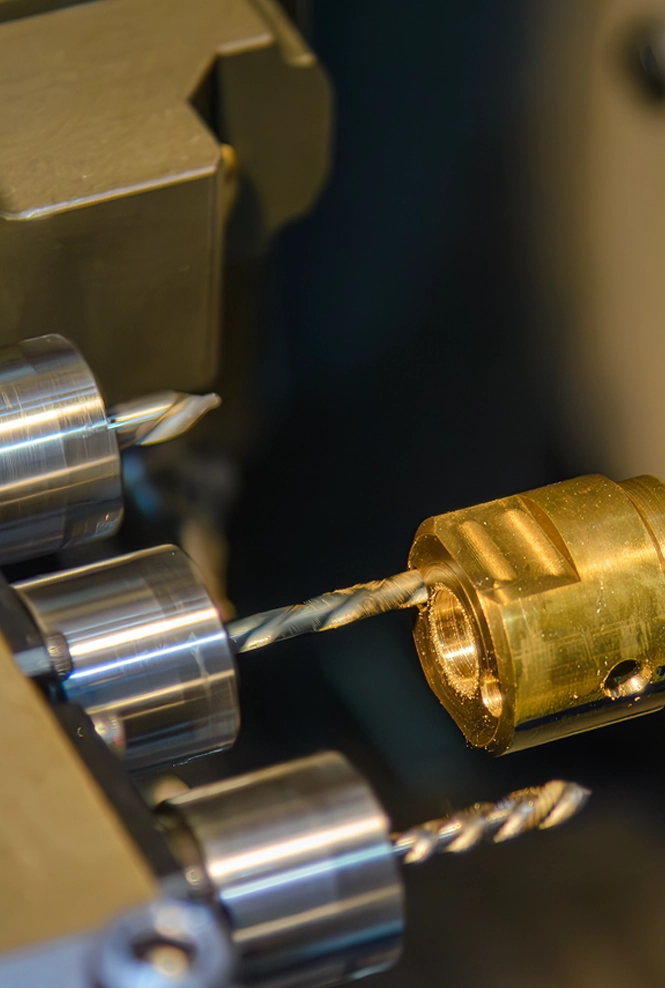

Machined Components

CSI delivers high-precision machined components that meet the exacting standards of today’s OEMs and tiered suppliers. Whether you’re seeking tight tolerances, complex geometries, or specialty materials, our global factory network — supported by CSI’s in-house engineering and U.S.-based logistics — ensures consistent quality, high scalability, and delivery timelines you can count on.

CSI’s machining operations are built to meet your demanding requirements without compromising flexibility or speed to market.

Our Capabilities

CSI’s precision-machined components are engineered for consistency, complexity, and scale. Our facilities support a full spectrum of subtractive manufacturing processes — including CNC turning, milling (3- to 5-axis), drilling, and grinding — across ferrous, non-ferrous, and engineered plastic materials.

We work closely with your team to define the ideal combination of process, material, and finish for your application. From CNC milling and turning to multi-axis, Swiss, and EDM machining, CSI provides reliable parts that are built to spec, built to scale, and built to last.

Machining Processes:

- CNC milling and turning

- Multi-axis machining

- Swiss machining

- Live tooling and bar-fed machining

- Hard turning

- Grinding and polishing

- Heat treating

- Secondary assembly, packaging, and kitting

Materials We Machine:

- Carbon and alloy steels

- Stainless steel

- Cast iron

- Aluminum

- Brass

- Bronze

- Copper

- Plastics including ABS, nylon, acetal, and PTFE

- Exotics and hardened alloys on request

If needed, CSI will help you select the right material, provide finishing services, as well as kitting and assembly services for a variety of applications.

Certified Quality You Can Count On

Every component we deliver is backed by rigorous quality assurance and ISO 9001:2015 certification — so you can trust what you get from CSI.

Finishing Options

The job isn’t done when a part comes off the line! CSI offers a wide range of finishing services to enhance performance, protect against wear, and meet your exact specs — whether for aesthetics, corrosion resistance, or mechanical integrity.

Common Finishing Services Include:

- Powder coating

- Anodizing

- Zinc plating

- E-coating

- Heat treating

- Deburring and polishing

- And more

Ready to Build What’s Next?

Let’s turn your spec into a solution – and your supply chain into a competitive advantage.