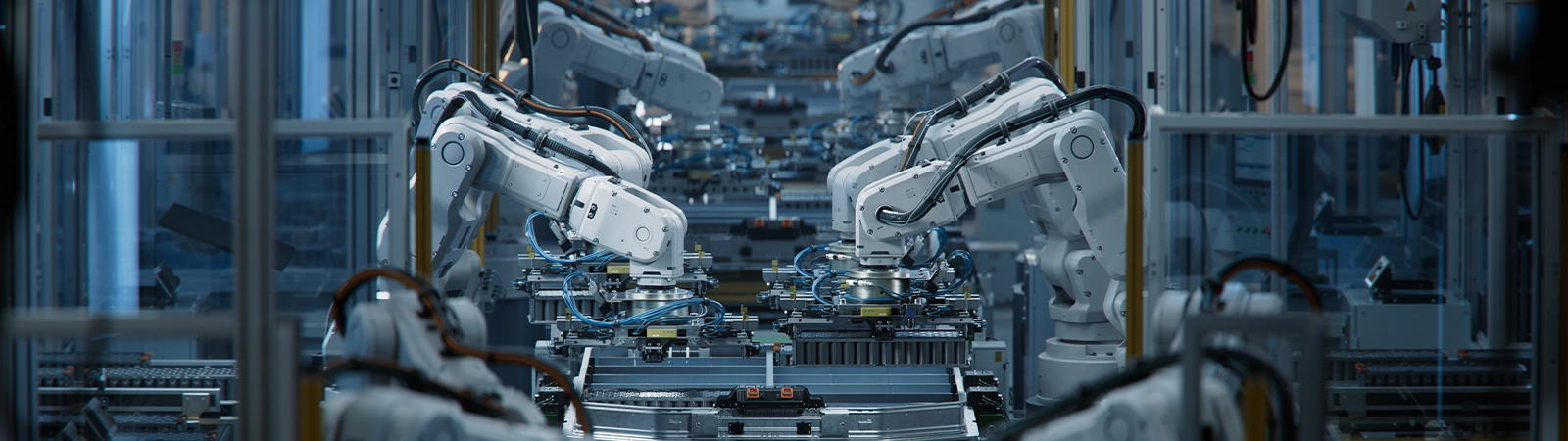

Industrial Equipment

Industrial systems demand components that perform consistently under pressure — cycle after cycle, year after year. From automation equipment and motion systems to pumps, compressors, and climate control technologies, industrial OEMs rely on CSI for parts engineered to withstand real-world operating conditions and continuous-duty performance.

We combine engineering expertise with a global manufacturing network to deliver reliable, scalable, and cost-effective solutions that keep your production lines running smoothly. Whether supporting next-generation equipment or sustaining legacy platforms, CSI provides precision, consistency, and supply chain strength you can count on.

Our Capabilities

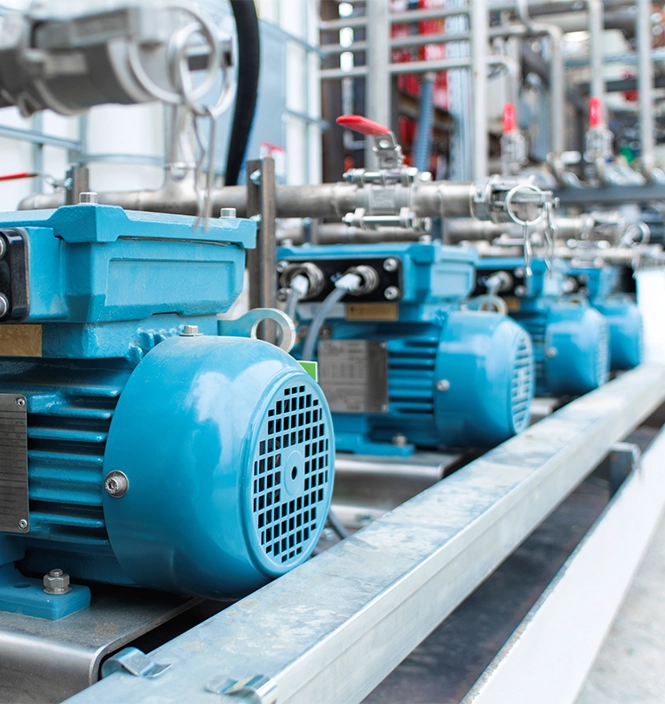

CSI supports diverse industrial applications — automation, motion control, power generation, fluid handling, HVAC, and beyond — with both component-level and system-level production support. Our global manufacturing network, in-house engineering, and quality-first culture make us the partner of choice for industrial innovators.

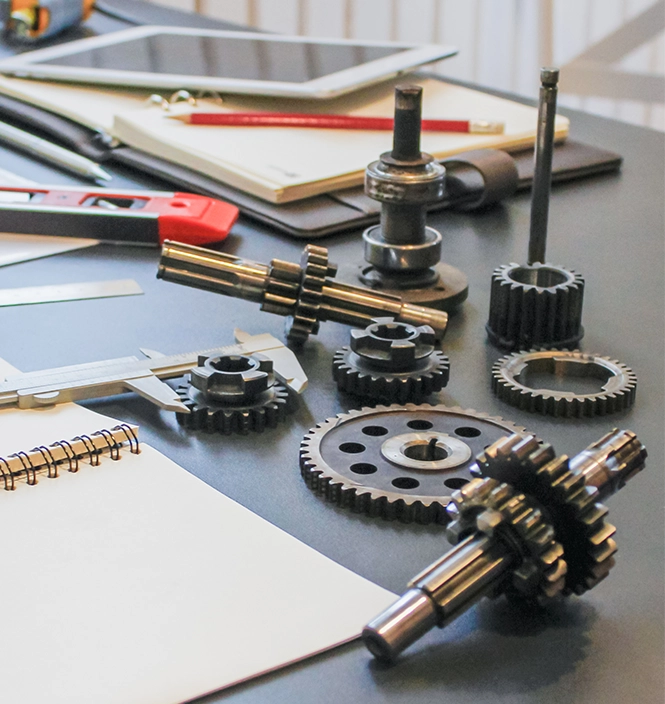

Typical Components and Processes:

- Precision Machined Parts: Housings, shafts, spindles, couplings, sleeves

- Cast and Forged Parts: Brackets, housings, impellers, manifolds

- Fabrications and Weldments: Frames, supports, and enclosures

- Stampings and Formed Metal: Guards, panels, and structural reinforcements

- Plastic Injection Molded Parts: Housings, handles, and control interfaces

- Wire Harnesses and Electrical Assemblies: Sensors, controls, and power units

- Turnkey Subassemblies: Pump and compressor assemblies, actuator systems, and motion modules

Services:

- Engineering and Design Support: From prototype to production readiness

- Rapid Prototyping: Quick-turn validation for new designs

- Global Sourcing and Logistics: Multi-region production, US fulfillment

- Testing and Quality Control: ISO 9001:2015, with APQP and PPAP rigor

- Kitting and Subassembly: Line-ready solutions to streamline your production

Ingenuity in Action: CSI for Industrial Equipment

We’ve helped OEMs enhance equipment reliability, optimize supply chains, and accelerate time-to-market through collaborative engineering and smart sourcing strategies. Here are some recent examples:

- Redesigned a modular support frame for a dimensionalizer producer, enabling standard-pallet shipping and improving stability without adding weight.

- Built a stable global supply base for long-lead, high-precision shafts by qualifying multiple international sources to ensure consistent quality and uninterrupted production.

- Recommended a higher-performance alternate material for a drivetrain component—improving mechanical properties while delivering more competitive pricing.

- Partnered with a customer to redesign a tensioner assembly, improving stability, reducing part count, and enabling CSI to advance the concept into manufacturable production.

Ready to Build What’s Next?

Let’s turn your spec into a solution – and your supply chain into a competitive advantage.