Heavy Equipment

From yellow iron to blacktop breakers, CSI is a trusted partner for OEMs in the heavy equipment sector. We deliver the high-performance parts and assemblies that help move mountains — sometimes literally. Whether it’s an undercarriage bearing, a welded subassembly, or G.E.T. and wear parts serving all major brands, our focus is on precision, durability, and delivery.

Our teams collaborate closely with your engineering and supply chain leaders to align part performance with production goals. We’re built for this industry’s complexity, from niche machine programs to large-scale legacy support.

Our Capabilities

CSI supports a wide range of heavy-equipment industries — including agriculture, construction, mining, aggregates, forestry, and material handling — with both individual components and complete subassemblies. Our global manufacturing reach and domestic responsiveness give OEMs the confidence to build and deliver at scale.

Typical Components and Processes:

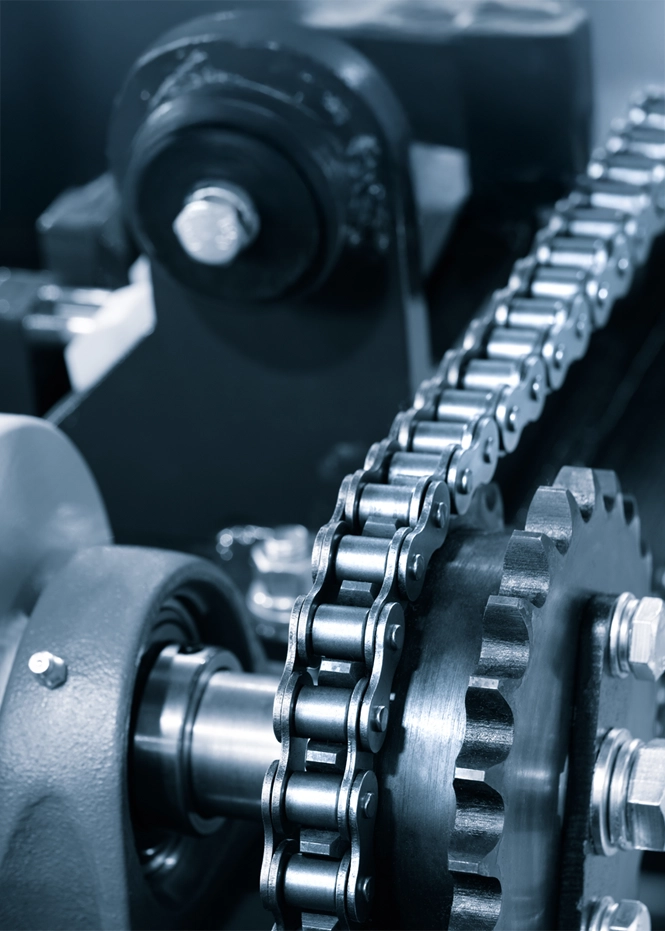

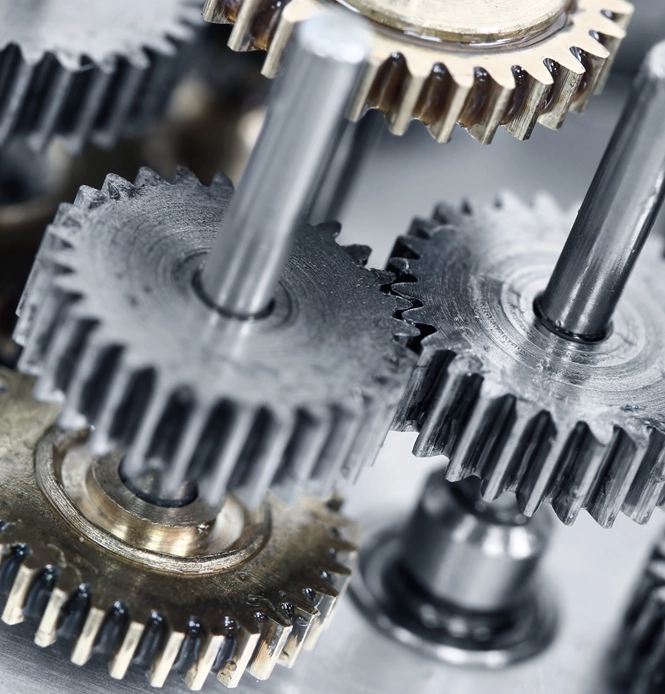

- Precision Components: Bearings, gears, sprockets, pulleys, pins

- Machined Parts: Housings, spindles, drive shafts

- Stampings: Brackets, structural panels, reinforcement plates

- Plastic Injection Molded Parts: Cable clamps, housings, covers

- Wire Harnesses: Lighting, sensors, controller cabling

- Fabricated and Welded Assemblies: Engine mounts, frames, railings

- G.E.T. and Wear Parts: Bucket teeth, shanks, compactors, blades, and more for all the top brands

Services:

- Engineering and Design Support: Collaborative product development and re-engineering

- Rapid Prototyping: Fast iteration for validation and fit

- Global Sourcing and Logistics: Just-in-time delivery and inventory management

- Testing and Quality Control: ISO 9001:2015, APQP, and in-process verification

- Kitting and Subassembly: Streamlined packages for OEM production lines

Ingenuity in Action: CSI for Heavy Equipment

We’ve worked with leading OEMs to support new machine platforms, redesign legacy parts, and develop streamlined aftermarket programs. Here are some recent examples:

- Built a stable global supply base for long-lead, high-precision shafts by qualifying multiple international sources to ensure consistent quality and uninterrupted production.

- Recommended a higher-performance alternate material for a drivetrain component—improving mechanical properties while delivering more competitive pricing.

- Partnered with a customer to redesign a tensioner assembly, improving stability, reducing part count, and enabling CSI to advance the concept into manufacturable production

Ready to Build What’s Next?

Let’s turn your spec into a solution – and your supply chain into a competitive advantage.